Announcing:

Expanding our support for the steel industry — beyond refractory brick and monolithics — we are now supplying graphite electrodes. Expect the same superior level of customer care that our company has cultivated over decades.

“We never just sell and disappear; rather, we treat our customers as partners, which they in fact are,” says Dan Ossola, founder, “We are here to answer questions, help troubleshoot, and follow up after the sale.”

In this way Ossola Industrials has earned the reputation not only as a trusted source for materials, but also a trusted resource for industry knowledge.

Collectively, our sales staff represents over 150 years of industry know-how, having previously held the same industry positions many of our customers are in: production, purchasing, mechanical, mill management, and process engineer. Yes, we understand your challenges because we have walked in your shoes.

Furthermore, we recognize that running the most successful electric arc furnace heat is as much an art as it is science. Tap into our industry knowledge — we are here to help you be successful.

Finished electrodes

Electrode showing nipple and pitch plug

Electrode showing threaded socket

Electrodes, packaged and ready for shipping

Graphite Electrodes and Furnace Efficiency

The manufacturing process is vital because both the quality of the raw materials and the surface integrity of the electrodes have a direct effect on the efficiency of the furnace. Our production facility utilizes only needle coke with longitudinal graphitization furnaces, resulting in reliable and consistent quality of product. Surface integrity is further enhanced by machining the electrode to exacting standards, including IEC, NEMA, and JIS specifications.

We produce all grades (RP, HP, SHP, UHP, HD) and sizes necessary to achieve your efficiency goals.

Note: Please see our Graphite Electrode General Properties chart. This link is to a pdf which can be printed for handy reference. We serve the USA, Canada, and Mexico.

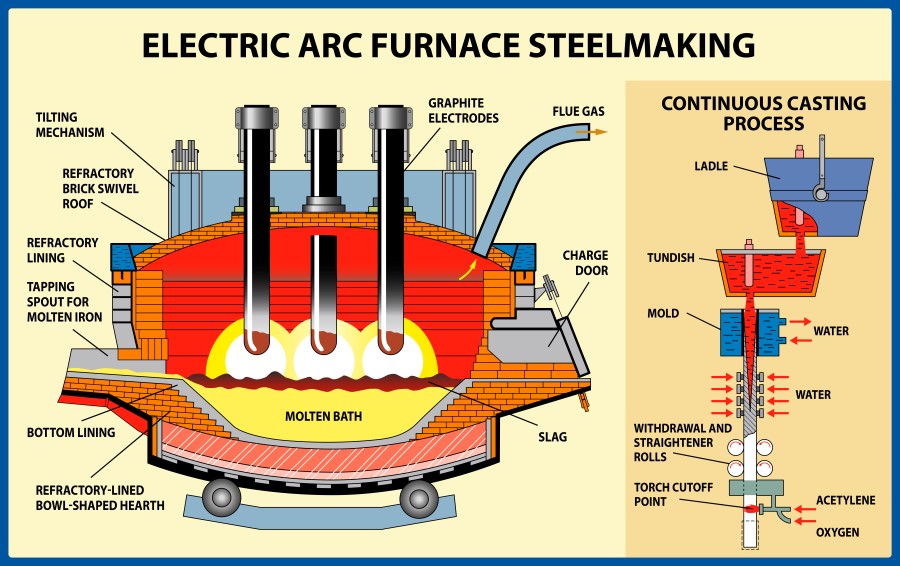

Graphite Electrodes in the Electric Arc Furnace

A graphite electrode conducts electricity along its cylindrical shape, and the electricity flows down the outside surface. For this reason, the quality or smoothness of the surface comes into play for how well it works – how efficient it is. Evaluating the efficiency relies on figuring the amount of scrap metal that can be melted per pound of electrode, which gets consumed in the process over time.

Furnaces are sized differently and require specific electrode length and diameters to match each furnace’s specifications. Therefore, the electrode itself must also be tall enough to fit properly in the furnace (as you can see in the diagram below.) This is accomplished by connecting shorter lengths of cylinder together via a male/female connector in each end of the cylinder. For example, 3 sections of 6’ cylinder would produce an 18’ graphite electrode. Additional electrodes sections can be added from the top, as needed, during the process.

Graphite electrodes are very furnace specific based on design, power input, and the customer’s conversion goals. Call us today to discuss your specific situation – we love talking this stuff!

Call 618-451-2621, and ask for Dan.